MSc thesis project proposal

A Microfluidic Cartridge for Quantum-Enhanced Magnetic Immunoassays

Motivation & Context

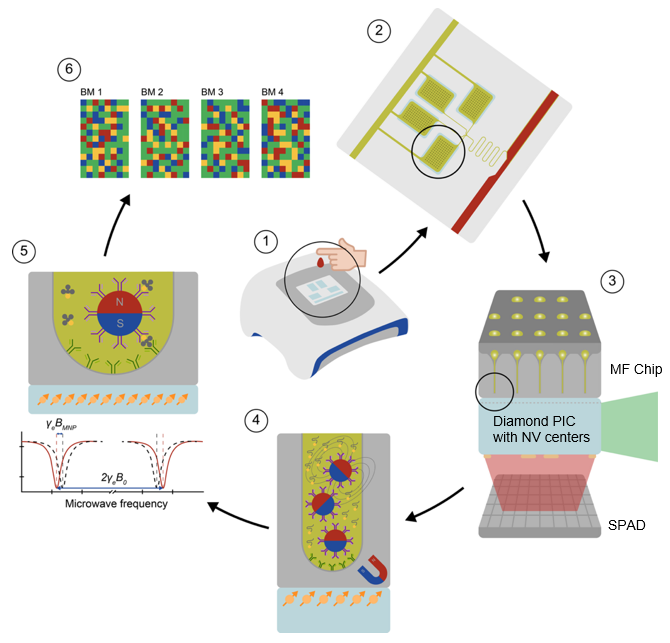

We are developing a quantum lab-on-a-chip platform that uses nitrogen-vacancy (NV) centers in diamond to detect biomarkers for sepsis and neurodegeneration. This system detects the magnetic noise generated by biomarkers or magnetic nanoparticles (MNPs) attached to target proteins. To validate this technology in practical conditions, we must transition from proof-of-concept physics experiments to a realistic microfluidic sensing environment. This requires a robust microfluidic interface capable of delivering precise concentrations of analytes to a 5 x 5 mm2 diamond chip without compromising the delicate quantum sensing conditions.

The sensitivity of NV centers in diamond is fundamentally limited by the standoff distance between the sensor and the target; the detection strength for magnetic dipoles decays rapidly with increasing standoff distance. Thus, key challenges include maintaining stable analyte delivery (to avoid issues such as evaporation or concentration drift) and maintaining an ultrathin sensor-to-sample distance for NV detection.

However, current NV sensing experiments rely on static droplets pipetted onto the diamond. These suffer from evaporation, lack reproducibility, and uncontrolled diffusion. There is no standardized "test bench" to dynamically vary biomarker concentrations. To bridge the gap to a practical Lab-on-Chip system, we need a detachable microfluidic cartridge that delivers fluid reliably and precisely controls flow, while maintaining the strict Z-standoff budget required for quantum detection.

Problem Statement

This project tackles several critical engineering requirements:

- The "Static Droplet" Bottleneck: Static measurements prevent precise characterization of the sensor's Limit of Detection (LoD) and Dynamic Range. A flow-based system is needed to create stable, known concentration gradients.

- The Detachability Challenge: Permanent bonding (e.g., plasma/glue) does not allow the expensive diamond sensor for future use. A reversible, leak-free docking mechanism is required to seal the microfluidics to the chemically inert diamond surface without damaging it.

- The Standoff Budget: The cartridge mechanics (gaskets, passivation layers) must not push the fluid too far from the sensor. NV-center magnetic sensors require the target MNPs to be extremely close to the NV layer for detection. Therefore, the microfluidic channel must be engineered to ensure that nanoparticles can diffuse or be transported to within tens of nanometers of the diamond surface (the active NV sensing layer), rather than merely flowing past at a distance.

- The Packaging Challenge: It is a challenge to package the system so that the diamond chip is attached to the microfluidic channel with minimal intervening material. We need to explore methods such as mechanical clamping, surface treatments, or UV-curable optical adhesives that can provide a tight seal to the diamond. Any bonding layer must be extremely thin to avoid degrading the sensor performance.

Assignment

The goal of this Master thesis project is to prototype a detachable microfluidic interface compatible with a wide-field microscope and use it to benchmark the diamond sensor's performance.

Core Goals:

- Cartridge Mechanics: Design, simulate, and fabricate a microfluidic interface in an appropriate material platform (PDMS, glass, etc.). Implement a detachable clamping or docking system that seals the manufactured microchannels to the diamond chip.

- Standoff Quantification: Engineer the surface stack (NV depth + passivation + fluidic boundary layer) and experimentally measure the signal decay from MNPs at distances ranging from 0 to 1 µm.

- Fluidic Validation: Demonstrate controlled flow of magnetically inert fluids vs. calibrated MNP concentrations to measure:

- Minimum resolvable Δ (concentration).

- Repeatability across multiple attach/detach cycles.

- Multi-Modal Lane: Implement a second flow lane for Radical/O2 sensing, testing if the same cartridge design supports the stricter (<50 nm) proximity requirements for these targets.

- Reporting.

Contacts:

Dr. Salahuddin Nur, s.nur@tudelft.nl

Dr. Massimo Mastrangeli, m.mastrangeli@tudelft.nl

Requirements

You are an ambitious, hands-on Master student with a background in (micro)electronics, applied physics or quantum engineering. You have an affinity for working in a multi-disciplinary context, including microfabrication, design and characterization of devices. You have good communication skills in English, you are independent and a team player.

Contact

dr. Massimo Mastrangeli

Electronic Components, Technology and Materials Group

Department of Microelectronics

Last modified: 2026-02-09